Simplifying how we isolate and preserve cells

Cells are not easy to handle. Whether they present as primary cell cultures or come from a continuous cell line, many things can go wrong when culturing them. Microbes can contaminate cell cultures and handling cells can come with hazards that require safeguards. A way to simplify cell isolation and processing would make developing new therapies against disease that much easier.

That’s a big reason why Semarion won SLAS 2025’s New Product of the Year Award. The company, spun out from the Cavendish Laboratory in Cambridge, UK, strives to make in vitro drug discovery easier by making cells easier to extract, store, and proliferate. Their solutions focus specifically on adherent cells as they are the most common medium for culturing cell lines.

And today, I have the honour of interviewing Semarion’s founder, Jeroen Verheyen. Now, hear from one of the makers of their newest platform, the Semarion SemaCyte. Read on to see how SemaCyte is ready to change how we isolate and experiment with cells across the life sciences.

The interview

What's wrong with current cell isolation methods?

PN: Your company began by developing ways to isolate and store cells. How do scientists current isolate and grow cells?

JV: Scientists can grow cells in two systems: adherent cultures and suspension cultures. Suspension cultures feature cell that float freely in a culture medium. Adherent cell cultures, the ones Semarion specializes in, grow cells as a single layer of cells on an artificial surface. This monolayer grips onto the surface for stability but must be detached when it’s time to isolate them. At that point, enzymes such as trypsin cut apart the proteins that anchor the cells so they can be processed, stored, and experimented upon.

PN: It sounds like a disruptive protocol, especially if you’re interested in keeping the cells intact.

JV: Cells aren’t used to being barraged with trypsin and similar enzymes. At the concentrations we use for protocols, trypsin and other enzymes can cause a lot of cellular stress. To survive the stress, cells would alter their gene expression and change their morphology. Although the cells remain alive, they end up not becoming what they were when they were first isolated. The fact cells change their morphology like so yields inconsistent assay results and reduces reproducibility in experiments. Yet, despite the damage they cause to data on cells, these protocols remain standard procedure.

SemaCyte: Preserving Adherent Cells

PN: Now’s the time to introduce everyone to your flagship solution. Tell us how the SemaCyte platform works and gets past the problems we’ve seen for isolating cells.

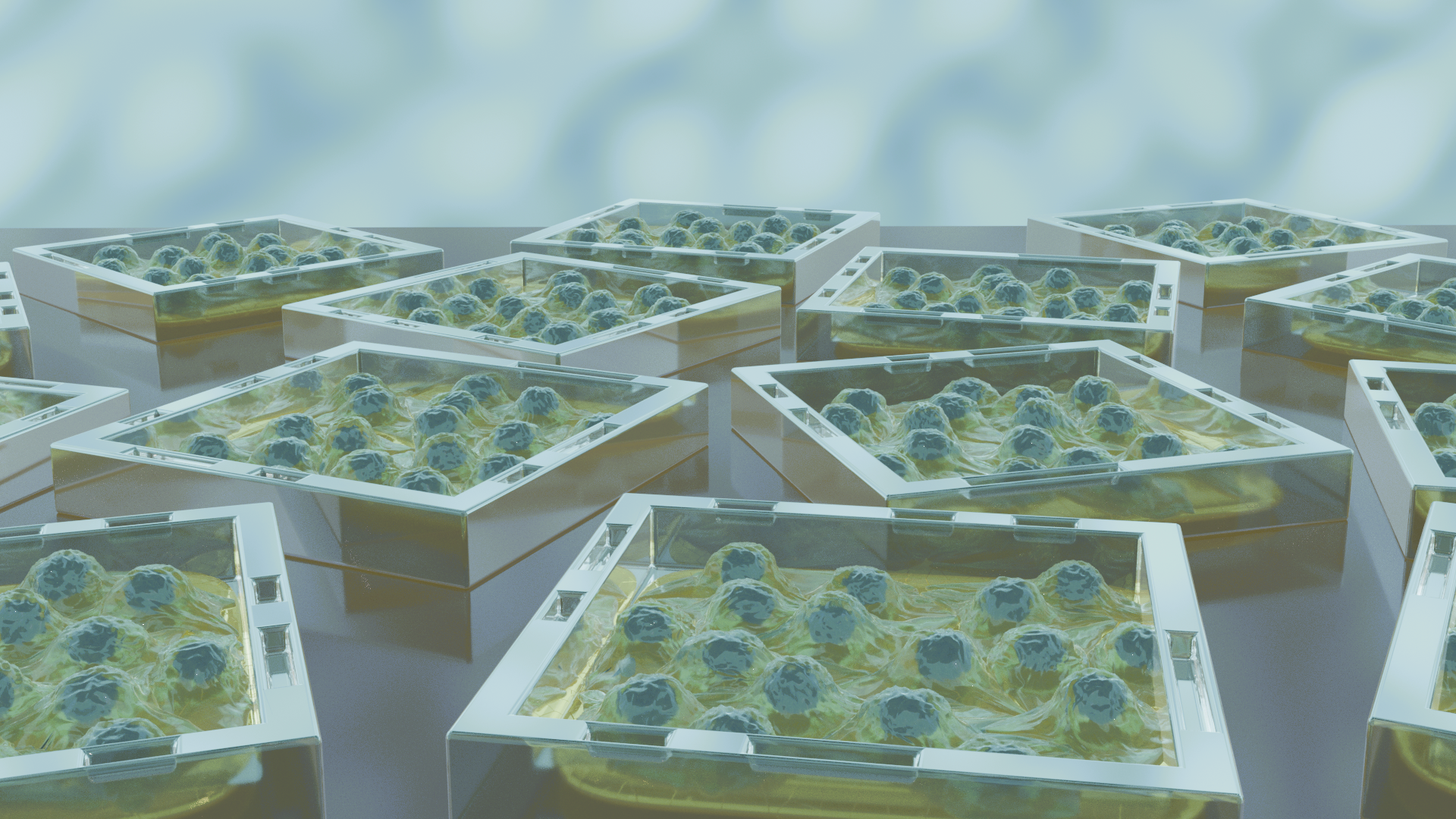

JV: The SemaCyte platform is a barcoded microcarrier platform that keeps cells attached throughout a cell culture workflow. Each of the microcarriers is 140 x 140 mm wide and functions as a microscopic petri dish where cells can grow on a flat surface. Each of the slots can hold up 1-30 cells which makes single-cell isolation much easier as well. With our platform, you won’t have to detach cells at all. You can keep the natural state and function of your cells and feel confident with your data’s reproducibility. Furthermore, you can use the microcarriers in suspension-based workflows that are more compatible with automation and high-throughput screening.

PN: How did you come up with the idea to produce microcarriers?

JV: We have a stellar team of scientists who have an engineering or a biology background. Our co-founder, Tarun Vemulkar, has experience working with semiconductors. He came up with the idea to use a photocurable polymer and nanometre-thick layers of ferromagnetic material for the microcarriers. Then, we designed the dimensions with microfabrication techniques we learned from the semiconductor industry.

How SemaCyte enables automation of cell culturing and assaying

PN: SLAS is all about automation and robotics. How does your platform integrate automation and high-throughput experimentation in cell-based workflows?

JV: We specially engineered the SemaCyte microcarriers to be seamlessly integrated into automated workflows. SemaCyte microcarriers can be dispensed into 384-well plates so that you can run hundreds of multi-model experiments efficiently. You can also run experiments with greater flexibility and miniaturize your assays, so you minimize sample and reagent usage while you grow your cells. You can also use our microcarriers on any standard lab equipment you have, including liquid handlers, plate readers, and high-throughput screening systems. Altogether, SemaCyte offers a new solution for growing and isolating adherent cells that is automation- and robotics-friendly. Whether you’re optimising miniaturised assays or conducting large-scale drug screens, our technology accelerates data acquisition and ensures reproducibility across the board.

PN: You may have the ability to run hundreds of experiments, but how would one distinguish between the cells within the run?

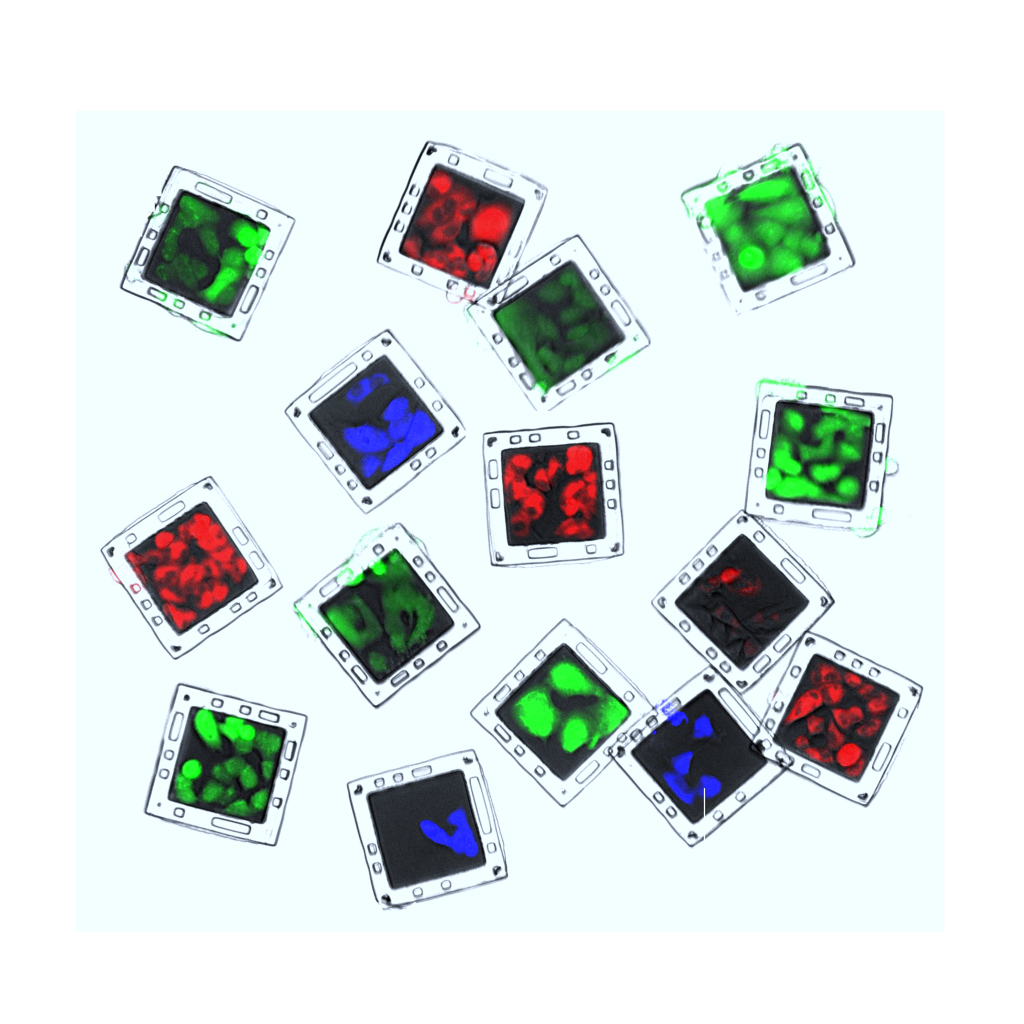

JV: The SemaCyte microcarrier uses optical barcodes. They’re like QR codes but visible by a microscope. A carrier harbouring a unique barcode would contain a unique cell type. With this setup, we can assay up to 10 different cell types within the same well of a 384-well plate (Figure 1).

PN: They remind me of the DNA barcodes I worked with when I prepared libraries in sequencing protocols.

JV: Exactly. You must know how much extra work it takes to deconvolute barcodes from sequencing data. But what’s so amazing about our barcodes is that you can use standard imaging equipment to see them. It means you can tell which wells contain which samples within seconds as opposed to waiting for a sequencing run to finish.

PN: Fascinating! I love the combination of engineering and biology you used to develop the microcarriers. It’s played a huge role in you winning the SLAS New Product Award. How do you feel winning the award, and how will it help Semarion continue to develop tools for storing and preserving small colonies of adherent cells?

JV: Winning the SLAS New Product Award of the breakthrough potential of the SemaCyte platform. It’s a recognition not only of the innovative technology we’ve developed but also of the need for better solutions in adherent cell assays. This award provides industry visibility, which will help us expand our collaborations and bring the technology to more labs globally. By continuing to innovate around cell storage, multiplexing, and assay readiness, we aim to further empower researchers to conduct faster, more reliable, and scalable experiments that push the boundaries of drug discovery.

Author

-

Paul Naphtali is a seasoned online marketing consultant. He brings to the table three years of online marketing and copywriting experience within the life sciences industry. His MSc and PhD experience also provides him with the acumen to understand complex literature and translate it to any audience. This way, he can fulfill his passion for sharing the beauty of biomedical research and inspiring action from his readers.

View all posts