Introduction: The more analyte, the more light is absorbed

Obtaining analyte concentrations is an essential component of life sciences research. We measure DNA concentrations to secure enough genetic material for sequencing. We also measure the concentrations of various compounds to optimize a drug candidate’s pharmacokinetics and pharmacodynamics. Measuring protein abundances also helps us secure high protein yields for synthetic biology and biotechnology experiments.

What’s amazing is that we have a straightforward metric for determining the concentrations of various compounds: absorbance. At its core, absorbance determines how much light is absorbed within a solution. If a solution comprises a single solute, we can know how much of the solute is present based on how much light the solute absorbs.

Absorbance measurements are typically done with a UV-Vis spectrophotometer that emits light within the visible and UV wavelengths. However, efforts to quantify absorbance with multiple samples struggle with problems that hamper the accuracy of such measurements. Minimising meniscus effects, reducing sample usage, and detecting high concentrations remain struggles that existing spectrophotometers face.

That’s until PHABIOC developed the SpecPlate.

As one of the Innovation AveNEW companies for SLAS Europe 2025, I had the pleasure of interviewing Jannik Jungmann, Co-Founder and CEO of PHABIOC. He walked me through the SpecPlate and how companies have already begun using the SpecPlate to push drug development forward.

Read more about this technological breakthrough by checking out the interview below.

The Interview

Absorbance: a primer on measuring analyte concentrations

PN: As part of your participation in SLAS Europe 2025, you’ll be showcasing the SpecPlate, a revolutionary 96-well plate set to usher in a new era of absorbance measurements. But what is absorbance, and why should we measure it in a sample?

JJ: Light can occur as waves, whether we see them or not. These waves, like the waves of the sea, can occur at different lengths, known as wavelengths. When light waves encounter a substance in a solution, they can get absorbed. The extent through which these substances absorb light waves is known as absorbance.

We can measure absorbance as a proxy of a solute’s concentrations thanks to the Beer-Lambert Law (Figure 1). This law which states that a compound’s absorbance is linearly correlated with the compound’s concentration in a solution.

A = e * c * L

Figure 1. The Beer-Lambert Law demonstrates the linear relationship between a solution’s absorbance with the concentration of the absorbing species. e represents the proportionality constant, c is the concentration of the absorbing species, and L is the path length of the light beam through the solution.

Because this law applies to all kinds of substances, we can use it to measure the concentrations of many compounds for various life science applications. We can measure microbial growth in live biotherapeutics (LBPs) by measuring the absorbance of microbial cultures at 600 nm (OD600). We can also monitor chemical reactions by observing decreases or increases in absorbance whenever a compound is metabolized or produced. We can also monitor changes in a solution’s colour to examine reaction kinetics.

PN: With so many applications for absorbance, you’d figure that measuring it would be a complex task.

JJ: That’s the amazing thing about absorbance. With the tools we have today, all you need is a device that measures the intensity of light before and after it passes through a sample. Typically, we would use a UV-Vis spectrophotometer to do that.

Measuring absorbance must be more reproducible

PN: So, what’s the real issue with how absorbance is commonly measured in the lab?

JJ: The lack of reproducibility and the constant need for dilution steps, especially when working with high concentration samples, represents the biggest issue with how we currently measure absorbance.

Most standard plates or cuvettes were never really optimised for modern UV/Vis workflows. With traditional methods, you’re forced to dilute your samples to stay within the readable absorbance range. In the process, every pipetting step introduces potential error and consumes time and reagents. On top of that, conventional well plates create a curved liquid surface – a meniscus – that varies depending on buffer, volume, and sample properties. This curvature alters the optical path length, which directly affects how accurately you can apply the Beer-Lambert Law. Even small changes to the meniscus can lead to inconsistent results across wells – especially in high-throughput settings.

The SpecPlate improves the reproducibility of absorbance measurements

PN: I can see why you developed the SpecPlate now. What features did you develop for the SpecPlate that address the shortcomings of measuring absorbance with a spectrophotometer?

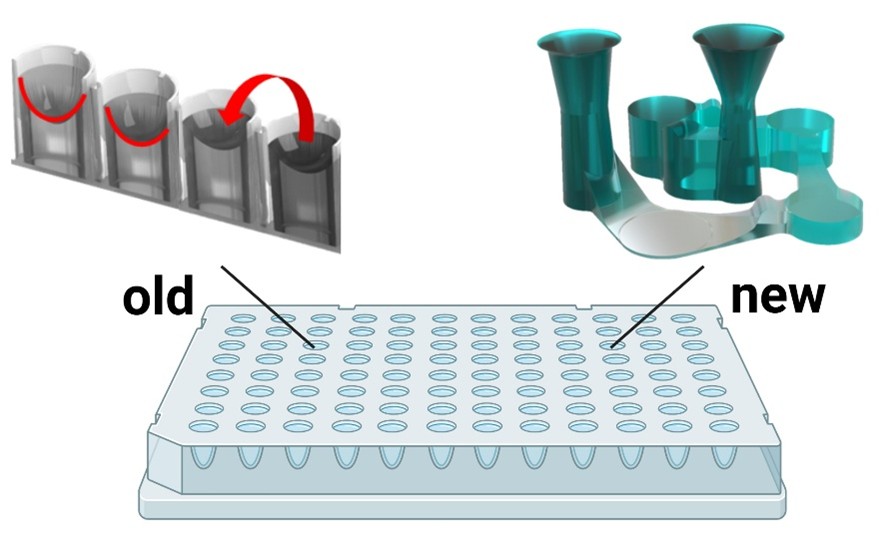

JJ: SpecPlate was designed to solve two key challenges in UV/Vis absorbance measurements: the need for dilution and poor reproducibility caused by meniscus effects (Figure 2).

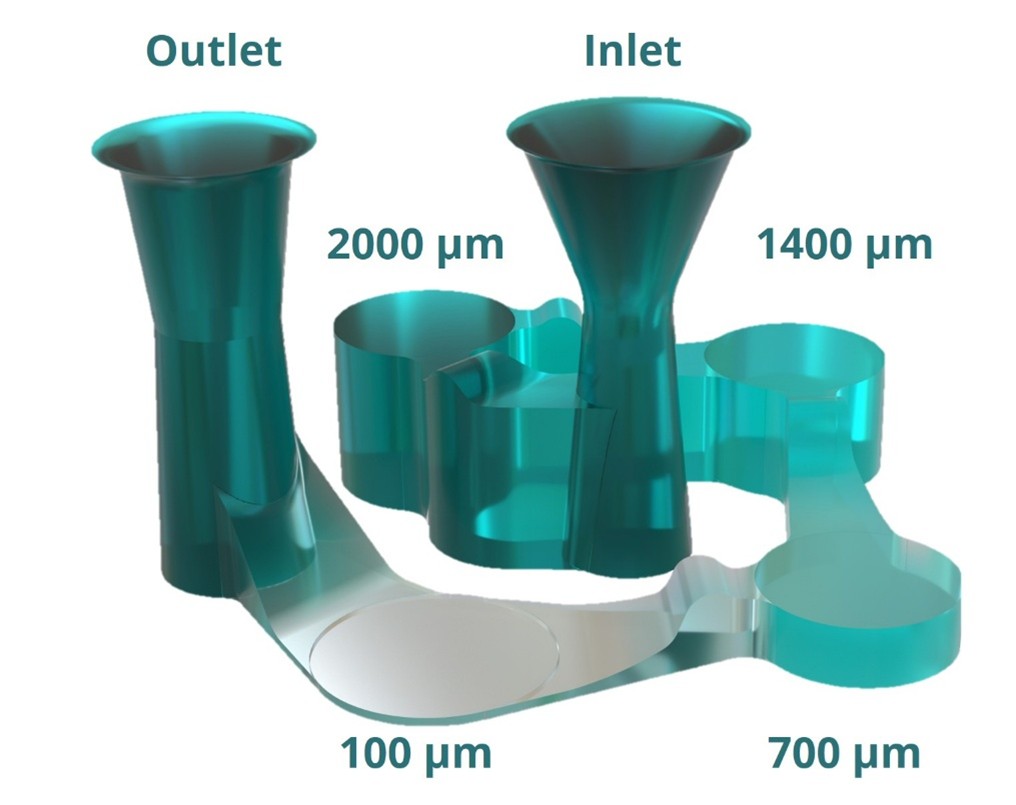

- Variable optical path lengths: Instead of changing the concentration of the sample, we control the optical path length through four closed chambers with defined cavity heights – from 100 µm to 2000 µm (Figure 3). This allows scientists to measure a wide concentration range directly in the original sample, without dilution. It’s a practical application of the Beer-Lambert Law – using path length, not pipetting, to adjust the measurement range.

- No dilution, less variability: Removing dilution steps means fewer pipetting errors, less sample handling, and more reproducible data – especially important when working with high-throughput screening or valuable drug candidates.

- Meniscus-free design: Standard microplates often have inconsistent light paths due to liquid curvature – the meniscus. We solved this by using flat, cuvette-like cavities in a closed format. Every sample is measured under identical optical conditions, which significantly improves reproducibility.

- Automation-ready: SpecPlate is built to fit seamlessly into automated workflows. Whether in pharma, biotech, or CRO settings, users can run precise absorbance measurements with minimal sample preparation.

In short: SpecPlate simplifies workflows, reduces error sources, and increases confidence in absorbance data – especially in the high-throughput, high-concentration applications where standard plates reach their limits.

PhaBioc at SLAS Europe 2025

PN: I can see that you being selected for SLAS Europe 2025 is well deserved. Congratulations on the selection! How will receiving this honour help you commercialize SpecPlate?

JJ: Thank you! We’re truly honored to be selected as an Innovation AveNEW company for SLAS Europe 2025. For us, the conference is more than just visibility – it’s a key milestone in our commercialization journey for SpecPlate.

SLAS gives us direct access to exactly the kind of stakeholders we want to work with – life science innovators, pharma developers, automation experts, and decision-makers from screening labs and CROs. Here’s how we’ll use this opportunity to accelerate adoption:

- Strategic partnerships with automation and instrument providers: We aim to collaborate with both automation companies and instrument manufacturers to ensure full compatibility of SpecPlate with existing systems. By doing so, we can maximize usability for end users and unlock the full value of the technology across high-throughput environments. SLAS provides the perfect setting for starting these conversations and showing the benefits live on site.

- Dialogue with CROs and screening labs: These groups will benefit directly from SpecPlate’s ability to measure drug concentrations and reaction kinetics without the usual dilution or meniscus-related errors.

- Raising awareness through content and campaigns: Alongside the event, we’re launching targeted digital campaigns and sharing thought leadership on the limitations of standard UV/Vis plates – and how SpecPlate solves them.

Altogether, SLAS Europe 2025 is the ideal stage for us to show that SpecPlate isn’t just a new product. It’s a better standard for absorbance-based analytics in modern drug development and formulation research.

Author

-

Paul Naphtali is a seasoned online marketing consultant. He brings to the table three years of online marketing and copywriting experience within the life sciences industry. His MSc and PhD experience also provides him with the acumen to understand complex literature and translate it to any audience. This way, he can fulfill his passion for sharing the beauty of biomedical research and inspiring action from his readers.

View all posts